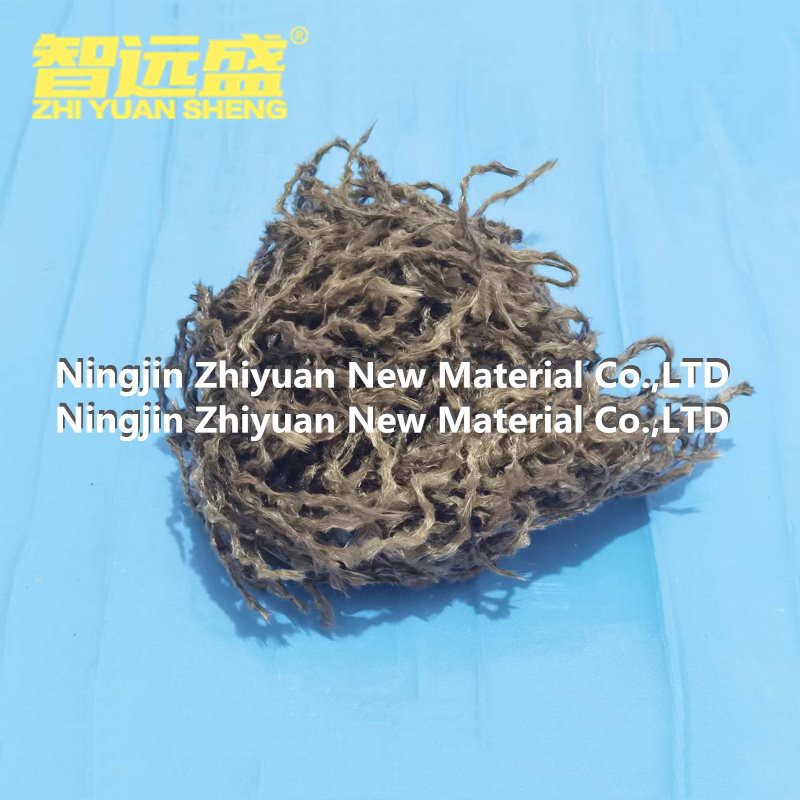

Basalt Fiber Packaging Material

Non-corrosive advantage for basalt fiber packaging material, make it impervious to attacks from alkali, chemicals, or water. This advantage makes it resistant to attack by acids, salts, and other corrosive substances.

- Product Introduction

Your Leading Ningjin Zhiyuan New Material Supplier

Ningjin Zhiyuan New Material Co., Ltd. was established in 2002, mainly committed to the development, production and sales of sound-cancelling, heat insulation and high performance heat resistant fiber products.

Why Choose Us

100% Satisfaction Guarantee

We're so confident you'll be happy with our services, we guarantee it.

Extensive Experience

Our team of professionals have been in the business for quite some time. Let us deliver solutions that work the first time!

Fair & Competitive Pricing

Our pricing structure is designed to make a modest profit so that we can continue to be a Hero another day.

Basalt Fiber Sound Insulation Cotton

Basalt Fiber Sound Insulation Cotton is a new type of environmental protection material with excellent sound insulation effect. It is made of natural basalt fiber as raw material and processed by special process.

When looking for efficient noise control methods, Basalt Fiber Silencer Cotton becomes a compelling choice. This innovative material combines the excellent properties of basalt fibers and opens up new possibilities in the field of acoustics.

Basalt Fiber Yarn has excellent performance, such as high strength, high modulus, high temperature resistance, corrosion resistance, good insulation, etc., can be widely used in textile, construction, transportation, aerospace and other fields.

Basalt Fiber Silencing and Heat Insulation Cotton

With the continuous progress of science and technology and the increasing awareness of environmental protection, Basalt Fiber Silencing and Heat Insulation Cotton, as an emerging environmental protection material, is gradually taking a place in the construction industry.

High Temperature Insulation Basalt Exhaust Tape

High Temperature Insulation Basalt Exhaust Tape is a fireproof material, usually used for heat insulation and fire protection in high temperature environments. This material is made of basalt fiber and has high fire resistance and heat insulation properties.

High Temperature Braided Basalt Sleeve

With the continuous progress of industrial technology, the requirements for material properties are becoming higher and higher. As a new kind of material, High Temperature Braided Basalt Sleeve is widely used in many fields due to its excellent high temperature resistance, high strength and wear resistance.

High Temperature Insulation Basalt Needle Felt

With the rapid development of the industrial field, the demand for high temperature insulation materials is increasing. High Temperature Insulation Basalt Needle Felt asa new type of heat insulation material, with its excellent high temperature resistance and excellent heat insulation effect, in many high temperature environment shows broad application prospects.

Basalt Fiber Packaging Material

With the growing global focus on environmental protection and sustainability, the packaging industry is facing major challenges in transitioning from traditional materials to green, recyclable materials.

Basalt Fiber Sound Insulation Cover

In modern society, with the urban construction and industrial development, noise pollution is becoming increasingly serious, which has caused no small impact on people's quality of life and working environment. In order to meet this challenge, Basalt Fiber Sound Insulation Cover, is emerging in the field of sound insulation with its unique advantages.

NON-CORROSIVE

Non-corrosive advantage for basalt fiber packaging material, make it impervious to attacks from alkali, chemicals, or water. This advantage makes it resistant to attack by acids, salts, and other corrosive substances.

NATURE FRIENDLY

Basalt fiber packaging material has a very important advantage, that all the world nowadays cares about it, that basalt fiber environmentally friendly, non-toxic and does not contain heavy metals.

SUSTAINABLE

Sustainable advantage in that mean, that their life span can exceed 100 years in many cases, unlike steel fiber which does not exceed 35 years in some cases.

RECYCLABLE

Basalt fiber packaging material has an advantage that can be recycled 100%, which means it can help reduce your carbon footprint. basalt fiber packaging material can be recycled easily through air or water filtration and reused in other products, such as construction, manufacturing, and electronics applications, which is a good in many fields.

LOW PRODUCTION COST

This an important advantage, basalt fiber packaging materials are made from basalt stone, which is abundant on the earth and easy to be processed. Therefore, it has low production costs, which make it an advantage where many company looking for.

HIGH TENSILE STRENGTH

Another for basalt fiber packaging material, that it is offers a unique combination of strength, toughness and affordable solution for any construction needs; its tensile strength is 2.5 times that of steel.

MOISTURE RESISTANT

Basalt fiber packaging material concrete has moisture resistant and temperature extremes more effectively than steel, wood, or plastic reinforcements, so it can be used in many outdoor applications such as bridges, roads, boat decks and marine construction.

HUMAN SAFETY

Another important for basalt fiber packaging material, that it's particles or fibrous fragments due to abrasion are too thick to be inhaled and deposited in the lungs, so it can't harm human, but care in handling is recommended.

Basalt Fiber Packaging Material and Its Manufacturing Process

Basalt fiber packaging material

Basalt fiber packaging material is a continuous fiber made of melting basalt stone at 1450 to 1500 degrees through Platinum rhodium alloy bushing. It is a new environmental protection fiber which is known as the twenty-first Century 'volcano rock silk', it is also called golden fiber because its color is golden brown.

Equipment and technology

The raw materials and energy are basalt, gas, electricity, and impregnating compound.The equipment is gas or electricity wire drawing kiln, Platinum rhodium alloy bushing, crusher, applicator, impregnating compound configuration and conveying equipment, roving machine and loom. Figure 2 has shown the manufacturing process and figure 3 has shown the flow chart.

Features of basalt fiber packaging material

Continuous high tensile strength

The tensile strength of basalt fiber packaging material is higher than that of steel fibers, aramid fibers, boron fibers, PBI fibers and alumina fibers, and is equivalent to that of S-glass fibers.

Excellent acid and alkali resistance

The acid and alkali resistance of basalt fiber packaging material is superior to that of aluminum borosilicate fibers.

High heat resistance stability

The heat resistance of basalt fiber packaging material is significantly better than that of glass, aramid, or carbon fibers, allowing continuous operation in the range -260℃ to 650℃. Furthermore, it can be combined with many other components to form even more heat-resistant materials.

Low moisture absorption rate

The moisture absorption of basalt fiber packaging material is one-sixth to one-eighth that of glass fibers.

High insulation and high transmission of electron magnetic radiation

It has high insulating properties and high transmission of electron magnetic radiation; it can be used in the manufacture of electronic insulating materials for high voltage (250KV) and constant voltage (500V) equipment.

Excellent strengthening effects and compatibility as a reinforcement for composite materials

It is compatible with plastics, metals, and concrete, allowing the development of composite materials with new properties. Single fiber stretching tests have demonstrated that the binding capacity of basalt fiber packaging material to epoxy polymers is higher than that of E-Glass fibers, which increases the strength and therefore the quality when used in place of glass fibers.

Environmentally friendly materials in line with the SDGs

As it is a natural material made from 100% basalt, it does not emit toxic gases or hazardous substances and is recyclable and environmentally friendly. Moreover, since it is made by melting in an electric furnace, no carbon dioxide is emitted in the production process of basalt fiber packaging material, making it a completely eco-friendly material. It also does not damage furnaces during incineration, as glass fiber does.

High insulation and sound insulation

It can be used as a highly efficient thermal insulator in low-temperature environments.

Basalt Fiber Packaging Material Application

Many building materials can be produced of basalt fiber packaging material. Basalt reinforcement for constructions and roads is effective way to achieve excellent results due to high mechanical properties and good chemical resistance of basalt fiber packaging material.

- Basalt reinforcement in form of mesh and scrim

- Geogrid mesh for road reinforcement

- Basalt rebars and pultruded profiles

- Basalt fiber packaging material reinforced concrete

- Read more about basalt building materials.

Automotive parts based on basalt fiber packaging material

Headliners

CNG cylinders

Basalt brake pads and clutch plates

Thermo insulation for exhausting systems

Muffler's filler

Interior and exterior parts based on fabrics

Parts and components of basalt fiber packaging material thermoplastic compound

Industrial filters production

Basalt fabrics for thermal barriers

Composite products in sport and leisure goods

Wind power generator blades

Corrosion resistant high pressure pipes

Marine application: Manufacturing of boats, yachts and jet boats hulls, surf boards etc

If you're in the market for high-quality basalt fiber packaging material, there are several factors to consider when making your purchase. First and foremost, you want to ensure that the rebar you buy is of good quality and meets the necessary standards for strength and durability.

In addition to quality, affordability is also an important consideration when buying basalt fiber packaging material. While the price of basalt fiber sound insulation cover can vary depending on the supplier and location, it is generally considered to be more affordable than traditional steel reinforcement in the long run due to its superior durability and longevity.

To find the best prices for basalt fiber packaging material, it's important to do your research and compare prices from different suppliers. Keep in mind that the cheapest option may not always be the best in terms of quality and durability, so it's important to consider other factors as well.

Another option to consider is purchasing basalt fiber packaging material online. Many suppliers now offer online purchasing options, which can make it easier to compare prices and find the best deals. However, it's important to be cautious when purchasing online and ensure that you are buying from a reputable supplier with a track record of providing quality products and excellent customer service.

When purchasing basalt fiber packaging material, it's also important to consider the quantity you need. Many suppliers offer bulk purchasing options, which can be more cost-effective in the long run if you have a large project that requires a significant amount of rebar.

Ultimately, the best place to buy quality basalt fiber packaging material at affordable prices will depend on your specific needs and preferences. Whether you choose to purchase from a local supplier or online, be sure to do your research and choose a supplier that offers high-quality products, competitive pricing, and excellent customer service.

What Factors Bolster the Sales of Basalt Fiber Packaging Material?

Basalt fiber packaging material is similar to carbon fibre and fibreglass, although it is less expensive than carbon fibre and has greater mechanical qualities. In addition to being utilised as a composite to produce a variety of end-use products, it is employed as a fireproof textile in the aerospace and automobile industries. Additionally, basalt fiber packaging materials keep their characteristics in freezing temperatures, are better acid resistant, and are inherently resistant to ultraviolet (UV) and high-energy electromagnetic radiation.

Owing to new stringent government rules and regulations the demand for environmentally friendly and easily recyclable fibre and composite products is increasing drastically. Many consumers prefer to use recyclable products which do not harm the environment. Developed countries such as the USA, Japan, and Germany are focusing on the use of environmentally friendly products rather than petroleum-based products.

These regulations are expected to persuade the producers and end-users to use natural fibre composites including basalt fiber packaging material in construction & infrastructure, automotive & transportation, electrical & electronics, marine & other end-use industries.

Our Factory

Ningjin Zhiyuan New Material Co., Ltd. was established in 2002, mainly committed to the development, production and sales of sound-cancelling, heat insulation and high performance heat resistant fiber products.

The main products: Fiberglass sound insulation cotton, Fiberglass pipe (Glass Fiber Tube), fiber Glass molded parts, basalt fiber sound insulation cotton, Fiberglass Needle Mat, basalt fiber Needle Mat, Fiberglass Heat Shield mat, basalt fiber Heat Shield mat, basalt fiber tube, basalt fiber strip, muffler Heat Shield, exhaust Heat Shield, Turbocharger Parts Heat Shield, purifier Heat Shield, Battery insulation cover, Generator Heat Shield, Engine sound insulation cotton, wiring harness Heat Shield, oil tube Heat Shield, fuel tank Heat Shield, Generator unit Heat Shield ETC.

FAQ

Q: How durable is basalt?

Let's explore these benefits and more below! Durability: Basalt slabs are highly durable and can withstand harsh weather, heavy foot traffic, and even vehicle traffic in some cases.

Q: What are the advantages of basalt fiber?

Q: Why is basalt so expensive?

Q: Is basalt fiber recyclable?

Q: Is basalt fiber stronger than carbon fiber?

Q: Is basalt fiber fire resistant?

Q: Is basalt fiber sustainable?

Q: Where is basalt fiber used?

Q: Is basalt a sustainable material?

Q: Is basalt fiber biodegradable?

Q: Can basalt replace steel?

Q: What color is basalt fiber?

Natural basalt fibers are generally brown in color. Basalt fiber is a new kind of inorganic environmental protection high performance fiber material, it is composed of silicon dioxide, alumina, calcium oxide, magnesium oxide, iron oxide and titanium dioxide and other oxides.

Q: Is basalt stronger than steel?

Q: What temperature does basalt fiber melt at?

The manufacture of basalt fiber requires the melting of the crushed and washed basalt rock at about 1,500 °C (2,730 °F).

Q: What is the thickness of basalt fiber?

Q: What is a basalt fiber?

Q: What fiber is the least flammable?

Q: Which fiber is the most resistant to flame?

Q: What is the origin of basalt fiber?

Basalt is a type of igneous rock formed by the rapid cooling of lava at the surface of a planet. It is the most common rock in the Earth's crust. Basalt rock characteristics vary from the source of lava, cooling rate, and historical exposure to the elements.

Q: Is basalt fiber expensive?

Arab Basalt Fiber Company is currently offering BFRP at a competitive price of $3 per pound or $5000 to $7000 per ton, making it an affordable option for those interested in using BFRP for their construction projects.

Hot Tags: basalt fiber packaging material, China basalt fiber packaging material manufacturers, suppliers, factory, Heat Insulation Fiberglass Lagging Tape, Heat Shield, Heat Shield for Engine Exhaust System, Basalt Fiber Yarn, Fiberglass Muffler Packing, Basalt Fiber Sound Insulation Cotton