Fiberglass Needle Mat

Needle mat is non-woven fiberglass material that is made of diverse size and form of glass fibers that are needle-felted in sheets. Material is needle punched to create monolith blanket in a required thickness.

- Product Introduction

Your Leading Ningjin Zhiyuan New Material Supplier

Ningjin Zhiyuan New Material Co., Ltd. was established in 2002, mainly committed to the development, production and sales of sound-cancelling, heat insulation and high performance heat resistant fiber products.

Why Choose Us

100% Satisfaction Guarantee

We're so confident you'll be happy with our services, we guarantee it.

Extensive Experience

Our team of professionals have been in the business for quite some time. Let us deliver solutions that work the first time!

Fair & Competitive Pricing

Our pricing structure is designed to make a modest profit so that we can continue to be a Hero another day.

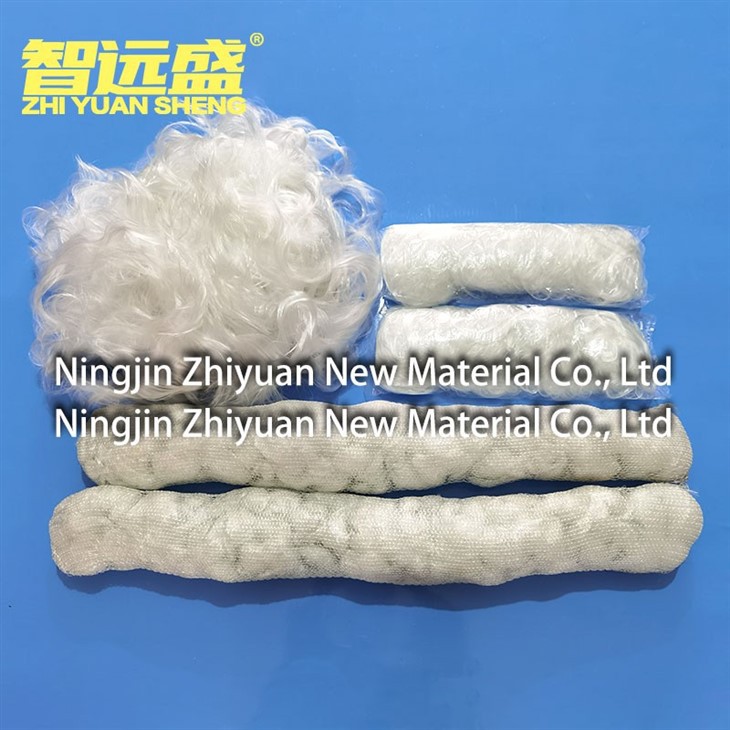

Motorcycle Silencer Fiberglass Products

Motorcycle Silencer Fiberglass Products also have good corrosion resistance. Motorcycle driving in a complex environment, the muffler may be eroded by water vapor, dust and other adverse factors. Glass fiber material can resist these erosion, maintaining the integrity and functionality of the muffler.

Fiberglass Sound Insulation Cotton

Fiberglass Sound Insulation Cotton is a sound insulation material made of glass fiber. It is usually used in various occasions that require sound insulation, such as buildings, cars, aircraft, etc.

With the continuous progress of science and technology, insulation materials are playing an increasingly important role in daily life and industrial production.

Fiberglass Exhaust Muffler Packing

Fiberglass Exhaust Muffler Packing is a material used to reduce exhaust noise, which has many advantages and a wide range of applications.One of the main advantages of Fiberglass Exhaust Muffler Packing is its excellent sound absorption.

Heat Insulation Fiberglass Lagging Tape

Heat Insulation Fiberglass Lagging Tape is used for high temperature parts of industrial equipment, such as boilers, heating furnaces, reactors, etc., which can effectively isolate heat sources and protect equipment from high temperature damage.

The main purpose of Fiberglass Muffler Packing is to reduce noise levels. When sound waves enter the muffler, they interact with the fiberglass filler, causing the energy of the sound waves to be absorbed and converted into heat.

Fiberglass Needle Mat is a kind of glass fiber products, including silica, alumina, calcium oxide, etc., with excellent performance. This material is glass ball or waste glass as raw materials, through high temperature melting, wire drawing, yarn, weaving and other processes made.

Fiberglass Silencer Cotton Molding Parts

With the rapid development of modern industry and construction technology, the problem of noise pollution has become increasingly prominent. Fiberglass Silencer Cotton Molding Parts, as an efficient and environmentally friendly mute material, has been widely concerned.

High Temperature Insulation Fiberglass Needle Felt

Among them, High Temperature Insulation Fiberglass Needle Felt has been widely concerned by the industry because of its excellent performance and wide application prospects.

Excellent Thermal Insulation: Interlocking fibers in the pin-cushion construction create air pockets that help reduce heat transfer and provide effective insulation.

High Chemical Resistance: Fiberglass needle mat can withstand the effects of many aggressive chemicals, ensuring long-term durability and reliability.

Good Sound Absorption: Its fibrous structure helps capture and dampen sound waves, making it an excellent choice for noise control in various industries.

Reinforcing Fiber Distribution: Fiberglass needle mat adopts advanced production technology to ensure uniform distribution of fiber structure and improve product consistency and overall performance.

Long Lasting: Fiberglass needle mat have excellent heat resistance, this heat resistance ensures a longer service life, thereby reducing the need for frequent replacement and associated costs.

Reduce Energy Consumption: Fiberglass needle mat help reduce energy consumption. The resulting energy savings can lead to significant cost reductions, increasing overall cost efficiency.

What Is Fiberglass Needle Mat

Needle mat is non-woven fiberglass material that is made of diverse size and form of glass fibers that are needle-felted in sheets. Material is needle punched to create monolith blanket in a required thickness.

What Are the Characteristics of Fiberglass Needle Mat?

As an important thermal insulation material, fiberglass needle mat plays an important role in construction, automobiles, aerospace and other fields. It has many unique characteristics that make it one of the most popular insulation materials. The following are the six main characteristics of fiberglass needle mat:

Excellent thermal insulation performance

fiberglass needle mat has excellent thermal insulation properties, and its low thermal conductivity can effectively reduce heat transfer, making it an ideal thermal insulation material. In winter, fiberglass needle mat can effectively block the penetration of cold outside air and keep the indoor temperature stable; while in summer, it can block the entry of high-temperature outside air and play a role in thermal insulation and cooling.

Good pressure resistance and durability

Due to its dense structure, fiberglass needle mat has high pressure resistance and durability. It can withstand a certain degree of pressure without losing its shape, while maintaining a stable thermal insulation effect for a long time and having a long service life.

Good fire resistance

Needle Mating Mat is an inorganic non-metallic material with good fire resistance. Under high temperature conditions, it is not easy to burn, does not produce toxic gases, has high safety, and is suitable for various occasions that require fire protection and heat preservation.

Good corrosion resistance

fiberglass needle mat has good corrosion resistance, can withstand the erosion of chemicals such as acids and alkalis, and is not easily affected by the external environment. This enables it to maintain stable performance in humid and corrosive environments and has strong applicability.

Convenient construction

Fiberglass needle mat has good flexibility and plasticity, and is easy to cut, fold and install. During the construction process, it can be customized on-site as needed to adapt to building structures of various shapes and sizes, improve construction efficiency, and reduce construction costs.

To sum up, glass fiber needle mat has many unique characteristics such as excellent thermal insulation performance, pressure resistance and durability, making it widely used in construction and industrial fields and becoming a favored thermal insulation material.

The Service Life and Moisture-Proof Methods of Fiberglass Needle Mat

As an important thermal insulation material, fiberglass needle-punched mat's service life and moisture-proof performance are the focus of users. In terms of service life, the evaluation and prediction of fiberglass needle mats is essential.

First of all, the service life of fiberglass needle mat is affected by many factors. Among them, the quality of materials and production technology are one of the key factors. High-quality fiberglass needle mat usually has higher density and uniform fiber distribution, which can provide better insulation effect and longer service life. In addition, factors such as construction quality, environmental conditions, and later maintenance will also affect the service life of fiberglass needle mat.

Secondly, regarding the moisture-proof performance of Silica Fiber Needled Mat, it is necessary to understand its moisture-proof principle and corresponding moisture-proof measures. fiberglass needle mat itself has certain moisture resistance, but it may still be corroded by moisture when exposed to a humid environment for a long time. In order to extend its service life and maintain good thermal insulation effect, some moisture-proof measures need to be taken. For example, during the construction process, you should try to avoid contact with water sources and ensure that the materials are kept dry before construction; during use, repair damaged parts in time to prevent water vapor from intruding; check and clean regularly to keep the surface dry, etc.

In addition, the moisture-proof performance of fiberglass needle mat can also be increased through coating and other methods. For example, using waterproof coating or covering with waterproof film can effectively prevent the penetration of water vapor and improve the moisture-proof performance of fiberglass needle mat. In addition, reasonable ventilation and drainage systems are also important means to prevent fiberglass needle mat from getting wet. Through reasonable design and settings, moisture can be effectively eliminated and the material kept dry.

Fiberglass needle mat or glass mats are non-woven reinforcement fibers for the production of fiber composite materials.

During production, fiberglass needle mats are interspersed with binders. During processing, the glass fiber mats are impregnated with polyester resin. The styrene present in the polyester resin causes the binder to dissolve. This allows the fiberglass needle mats to be easily draped into the desired shape.

Due to the disordered structure of the glass fiber mat, fiber composite materials produced with glass fiber mats have a lower proportion of fibers by volume than, for example, fiber composite materials with glass filament fabric or glass filament fabric.

fiberglass needle mat have a high drapability and are also cheaper than most other reinforcement fabrics.

When processing glass fiber mats, it is important to ensure that a glass fiber mat with a lower basis weight is used first in a multi-layer laminate structure. The lower the basis weight, the easier it is to drape the glass fiber mat. In the case of further layers, glass fiber mats with a higher basis weight can then be used to reinforce the fiber composite material.

First of all, fiberglass needle mats differ in terms of their basis weight. The most common types are 300 g/m² or 450 g/m².

In addition, the fiberglass needle mat is differentiated according to the binding type. There are powder-bonded fiberglass needle mats and emulsion-bonded fiberglass needle mats. The powder binding is based on a powdered polyester resin. The emulsion bond is based on a polyvinyl acetate/water mixture. The differences in the technical characteristics in the fiber composite material are only marginal due to technical progress. To a lesser extent, however, the following principles also apply. Powder-bonded fiberglass needle mats / glass mats are less drapeable. On the other hand, they are more water-resistant and the laminate is not clouded during lamination. Emulsion-bonded glass fiber mat / glass mat, on the other hand, is easier to process, but has less water resistance in the laminate and a milky veil occurs during lamination.

Is Fiberglass Needle Mat Insulation Mildew Resistant?

As an important thermal insulation material, fiberglass needle-punched mat's anti-mold performance is an important aspect of user concern. So, can fiberglass insulation be mildew-resistant? Below we will analyze the anti-fungal properties of glass fiber needle mat and introduce relevant experimental results.

First of all, fiberglass needle mat itself is an inorganic, non-metallic material that does not contain organic substances, so it is not susceptible to mold erosion. Compared with organic materials, fiberglass needle mat does not provide the necessary nutritional conditions for mold growth, such as moisture and organic matter. Therefore, in theory, fiberglass needle mat has certain anti-mildew properties.

Secondly, the experimental results also further verified the anti-mildew performance of glass fiber needle mat. In some experiments, fiberglass needle-punched mats were exposed to moisture and the surface condition was monitored over time. The results show that compared with some organic insulation materials, the surface of fiberglass needle mat is often less prone to mildew or mold growth. This is because fiberglass needle mat has good moisture resistance and can effectively prevent the penetration of moisture, thus reducing the conditions for mold growth.

In addition, the fire resistance of fiberglass needle mat can also affect its anti-mildew performance to a certain extent. Because Needled Mats has good high temperature resistance and is not easy to burn, it is not prone to mold growth even in humid environments. Some organic insulation materials are prone to mold growth under humid conditions and may accelerate mold reproduction because they contain organic matter.

Our Factory

Ningjin Zhiyuan New Material Co., Ltd. was established in 2002, mainly committed to the development, production and sales of sound-cancelling, heat insulation and high performance heat resistant fiber products.

The main products: Fiberglass sound insulation cotton, Fiberglass pipe (Glass Fiber Tube), fiber Glass molded parts, basalt fiber sound insulation cotton, Fiberglass Needle Mat, basalt fiber Needle Mat, Fiberglass Heat Shield mat, basalt fiber Heat Shield mat, basalt fiber tube, basalt fiber strip, muffler Heat Shield, exhaust Heat Shield, Turbocharger Parts Heat Shield, purifier Heat Shield, Battery insulation cover, Generator Heat Shield, Engine sound insulation cotton, wiring harness Heat Shield, oil tube Heat Shield, fuel tank Heat Shield, Generator unit Heat Shield ETC.

FAQ

Q: What is the use of fiberglass mat?

Q: What is needle mat?

Q: What is better fiberglass cloth or fiberglass mat?

Q: What's the difference between fiberglass mat and fiberglass cloth?

Q: Which is stronger fiberglass mat or fiberglass cloth?

Q: How many layers of fiberglass mat to use?

Q: Is fiberglass mat waterproof?

Q: Can you cut fiberglass mat?

Q: Why is fiberglass so good?

Q: Will fiberglass mat stick to plastic?

Q: Can you use fiberglass mat with epoxy?

Q: Is fiberglass mat flammable?

Q: What fiberglass mat to use on boat floor?

Q: How long do you have to lay on a needle mat?

Q: How much resin do I need for fiberglass mat?

Q: Is fiberglass mat heat resistant?

Heat Shieldings heat resistant Thermo Block is very heat resistant and suitable for all kinds of applications. The mat is both insulating and heat reflective and is easy to cut to size.

Q: What is the benefit of needle mat?

Q: How long should you use a needle mat?

Q: Why is fiberglass so toxic?

Q: What is 1708 fiberglass used for?

Hot Tags: fiberglass needle mat, China fiberglass needle mat manufacturers, suppliers, factory, Muffler Insulation Blanket, Basalt Fiber Silencing and Heat Insulation Cotton, Glass Fiber Needled Felt, Exhaust Insulation Blanket, Basalt Fiber, Fiberglass Needle Mat