Glass Fiber Needled Felt

The glass needle felt is made from 100% fiberglass and is heat resistant to temperatures up to 600 °C. Glass needle felt is made from long fibers which are needled together to form a very stable mat and are therefore made without any binder.

- Product Introduction

Your Leading Ningjin Zhiyuan New Material Supplier

Ningjin Zhiyuan New Material Co., Ltd. was established in 2002, mainly committed to the development, production and sales of sound-cancelling, heat insulation and high performance heat resistant fiber products.

Why Choose Us

100% Satisfaction Guarantee

We're so confident you'll be happy with our services, we guarantee it.

Extensive Experience

Our team of professionals have been in the business for quite some time. Let us deliver solutions that work the first time!

Fair & Competitive Pricing

Our pricing structure is designed to make a modest profit so that we can continue to be a Hero another day.

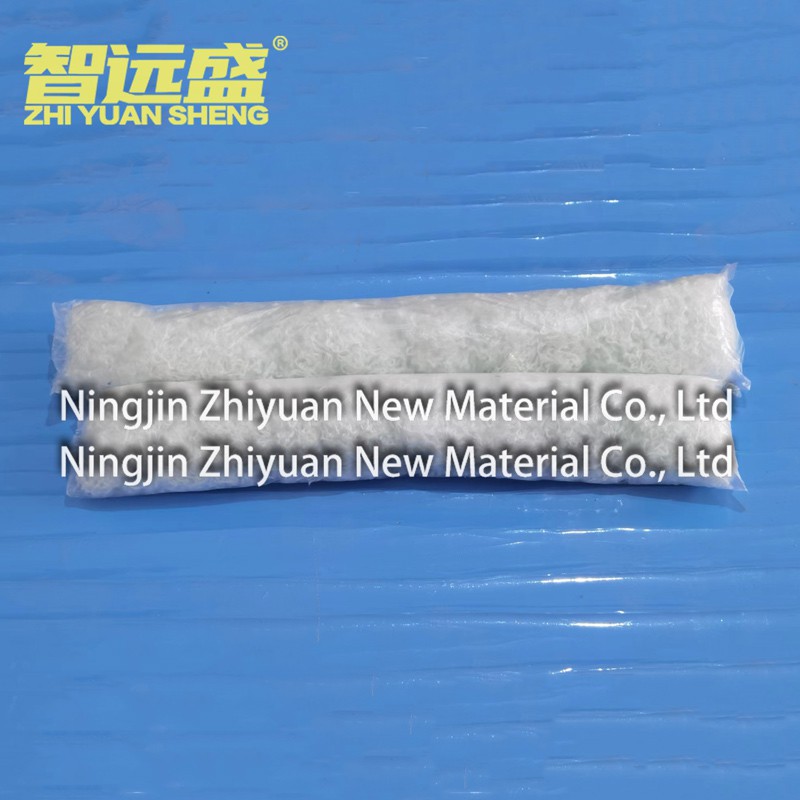

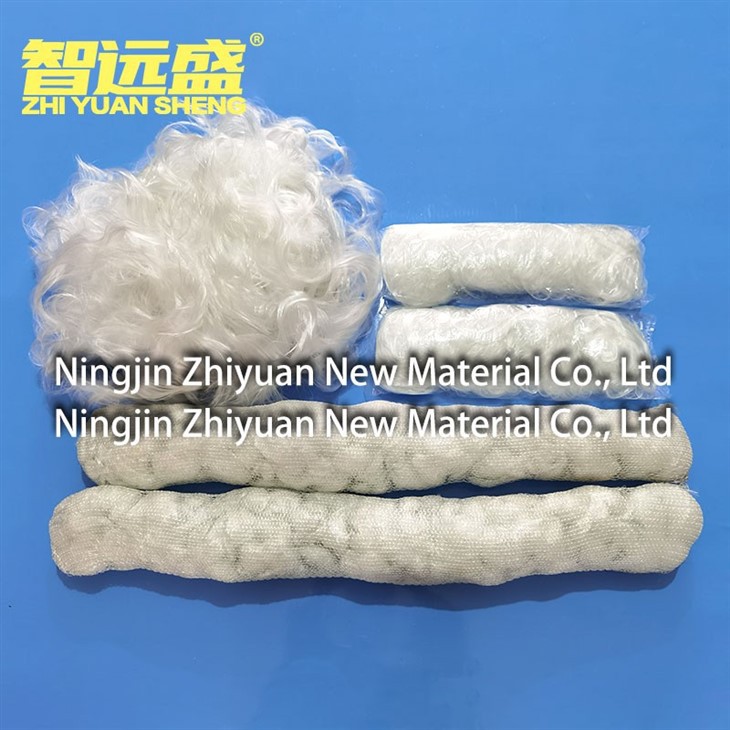

Motorcycle Silencer Fiberglass Products

Motorcycle Silencer Fiberglass Products also have good corrosion resistance. Motorcycle driving in a complex environment, the muffler may be eroded by water vapor, dust and other adverse factors. Glass fiber material can resist these erosion, maintaining the integrity and functionality of the muffler.

Fiberglass Sound Insulation Cotton

Fiberglass Sound Insulation Cotton is a sound insulation material made of glass fiber. It is usually used in various occasions that require sound insulation, such as buildings, cars, aircraft, etc.

With the continuous progress of science and technology, insulation materials are playing an increasingly important role in daily life and industrial production.

Fiberglass Exhaust Muffler Packing

Fiberglass Exhaust Muffler Packing is a material used to reduce exhaust noise, which has many advantages and a wide range of applications.One of the main advantages of Fiberglass Exhaust Muffler Packing is its excellent sound absorption.

Heat Insulation Fiberglass Lagging Tape

Heat Insulation Fiberglass Lagging Tape is used for high temperature parts of industrial equipment, such as boilers, heating furnaces, reactors, etc., which can effectively isolate heat sources and protect equipment from high temperature damage.

The main purpose of Fiberglass Muffler Packing is to reduce noise levels. When sound waves enter the muffler, they interact with the fiberglass filler, causing the energy of the sound waves to be absorbed and converted into heat.

Fiberglass Needle Mat is a kind of glass fiber products, including silica, alumina, calcium oxide, etc., with excellent performance. This material is glass ball or waste glass as raw materials, through high temperature melting, wire drawing, yarn, weaving and other processes made.

Fiberglass Silencer Cotton Molding Parts

With the rapid development of modern industry and construction technology, the problem of noise pollution has become increasingly prominent. Fiberglass Silencer Cotton Molding Parts, as an efficient and environmentally friendly mute material, has been widely concerned.

High Temperature Insulation Fiberglass Needle Felt

Among them, High Temperature Insulation Fiberglass Needle Felt has been widely concerned by the industry because of its excellent performance and wide application prospects.

Excellent thermal insulation: According to the physical principle, the thermal conductivity of the gas is small, and there are many air holes inside the excellent thermal insulation material. The glass fiber acupuncture cotton has innumerable tiny gas, and the fiber presents irregular arrangement, it is an excellent heat insulation material, thermal conductivity coefficient is 0.2-0.040kcal/ mhr. c between.

Will not burn: The main component of glass fiber is silicide (more than 50%), non-flammable, no deformation, no embrittlement, high temperature up to 700 °C.

Sound absorption rate is good: When the sound waves invade the glass fiber cotton, the period of energy due to the friction with the fiber and the size of the cavitation, and a lot of inhalation. In general, the sound absorption rate is as high as 90% or more, which is a good way to prevent noise interference.

High insulation: Glass fiber can be high temperature, good mechanical properties, and high chemical stability, is the best insulation material.

High corrosion resistance: Glass fiber is not afraid of strong acid, strong alkali, long time will not reduce its functional characteristics.

Good recovery: Glass fiber contains numerous fixed air pockets, excellent recovery. Not afraid of any shock and vibration, the tensile strength is more than 1.0kg.

Low moisture absorption: Moisture absorption rate is usually close to zero.

Light and soft: Compared with other insulation materials, glass fiber needle felt the lightest and most flexible, if installed on the machine, can reduce its weight and vibration load.

Simple construction: Size can be cut according to customers.

What Is Glass Fiber Needled Felt

The glass needle felt is made from 100% fiberglass and is heat resistant to temperatures up to 600 °C. Glass needle felt is made from long fibers which are needled together to form a very stable mat and are therefore made without any binder.

Glass Fiber Needle Felt Features

Good thermal damage: According to the physical principle, the thermal conductivity of gas is small. Excellent heat damage material with many air points inside. Glass fiber needle-punched cotton has countless small gases, and the fibers are irregularly arranged. It is an excellent thermal insulation material and has a thermal conductivity coefficient.

Non-combustible: The main component of glass fiber is silicide (accounting for more than 50%), non-combustible, no deformation, no embrittlement, high temperature resistance 7000C:

Good sound absorption rate: When the sound wave invades the glass fiber wool, due to the friction with the fibers and air pockets of different sizes, it can be inhaled in large quantities. Generally speaking, the sound absorption rate is as high as 90% or more, which is a good person to prevent noise interference:

High insulation: Glass fiber has high temperature resistance, good mechanical properties and high chemical stability, and is the best insulating material; 5. High corrosion resistance: glass fiber is not afraid of strong acid. Strong alkali, will not reduce its functional properties for a long time;

Good recovery: The glass fiber contains numerous fixed air pockets and has excellent recovery. Not afraid of any shock and vibration, the tensile strength exceeds 1.0kg.

Low moisture absorption rate: The moisture absorption rate is usually close to zero.

Lightweight and soft: Compared with other thermal insulation materials, fiberglass needle felt has the lightest weight. If installed on machinery, its weight and vibration load can be reduced.

Simple construction: The size can be cut according to customers.

What Are the Uses of Glass Fiber Needle Felt?

There are many kinds of glass fiber felt, including: glass fiber needled felt, glass fiber continuous raw silk felt, glass fiber chopped strand mat, glass fiber continuous monofilament felt, glass fiber surface felt, glass fiber roofing felt, stitching chopped Felt, roving fabrics, composite mats, sandwich composite felts, needle-punched composite felts, air-purified glass fiber fluffy filter felts, etc.

Glass fiber needle felt is widely used in carbon black, steel, non-ferrous metals, chemical, incineration and other industries. In China, industrial filter materials are the main application areas of glass fiber needle felts.

The glass fiber needle felt is used for decoration and sound absorption, heat insulation, shock absorption, and flame retardancy in the automobile. It contributes to the light weight of the automobile and the effective use of space; the needle felt can be compounded with the recycled fiber and can be used as Roof and door gaskets, engine hoods (adhered to the inside), engine and compartment partitions, trunk liners.

The effect of heat insulation and heat insulation possessed by the microporosity of the needle felt can be used for thermal insulation of various heat generating parts of the pipeline. The filtering and sound-absorbing effect of the needle felt can be used for sound-proof dust collectors of automobiles, motorcycles and general-purpose gasoline engines, and is widely used for sound insulation, moisture reduction, and fire prevention in hotels, entertainment places, and professional sound rooms.

The glass fiber needled felt is disorderly interleaved and interlaced, showing a non-directional three-dimensional micro-porous structure with small voids, large gaps, and good sound absorption, shock absorption, corrosion resistance, insulation, high temperature resistance, and flame retardant properties. High porosity, low gas filtration resistance, large filtration wind speed, high dust removal efficiency, and resistance to bending, abrasion resistance, and dimensional stability. Glass fiber needle felts are mainly used for the manufacture of thermoplastic sheet molding compounds AZDEL and polypropylene sheets (GMT) Reinforced substrate. In the past, glass needles were mainly used for continuous needled felts. However, after repeated comparisons and material selection, it was considered that the use of glass fiber chopped needle felts had better processing performance than the use of continuous glass fiber needle felts, mainly in glass. When fiber chopped needle felt and polypropylene are compounded, the fluidity is better.

Glass Fiber Needle Felt Application

1. For various heat sources (coal, electricity, oil, gas) high temperature equipment, central air-conditioning pipeline insulation;

2. For various thermal insulation and fireproof materials;

3. It is used for sealing, sound absorption, filtering and insulating materials in special places; 4. It is used for heat preservation of various heat transfer and heat storage devices;

4. It is used for sound insulation, heat preservation and heat resistance of automobiles, ships, airplanes and other parts; 6. The sound insulation of the inner core of automobile and motorcycle mufflers and the sound insulation of engines;

5.Heat. Chemical pipeline thermal insulation, thermal insulation effect is better than general thermal insulation materials;

6.Insulation of electrical siding in household industries such as air conditioners, refrigerators, microwave ovens, dishwashers, etc.; 10. Other occasions require heat preservation, heat preservation, fire prevention, sound absorption and insulation.

Glass Fiber Needle Felt Market Analysis and Latest Trends

Glass fiber needle felt is a type of non-woven fabric made from fine strands of fiberglass that are mechanically interlocked using a needle punching process. This material offers excellent properties such as high strength, durability, thermal resistance, chemical resistance, and low thermal conductivity. It finds various applications in industries such as automotive, aerospace, construction, filtration, and others.

The market analysis of the glass fiber needle felt market suggests that it is expected to witness significant growth during the forecast period. The increasing demand for advanced materials with superior properties in various end-use industries is driving the market growth. The automotive industry is a major consumer of glass fiber needle felt, as it is used for filtration, insulation, soundproofing, and reinforcement in vehicles.

The construction sector is also contributing to the market growth, as glass fiber needle felt is used for geotextiles, roofing materials, insulation, and reinforcement. The growing construction activities, especially in emerging economies, are expected to boost the demand for this material.

Moreover, the increasing focus on environmental protection and stringent regulations regarding emission control are driving the demand for filtration applications. glass fiber needle felt is used in filters for air, liquid, and gas purification applications, further driving the market growth.

In terms of regional analysis, Asia Pacific is expected to dominate the glass fiber needle felt market during the forecast period due to rapid industrialization and infrastructure development in countries like China and India. North America and Europe are also significant markets for glass fiber needle felt, driven by the presence of key end-use industries and strict environmental regulations.

In conclusion, the glass fiber needle felt market is projected to experience substantial growth in the coming years due to the demand for durable and high-performance materials in various industries. The market is expected to grow at a CAGR of % during the forecast period.

Our Factory

Ningjin Zhiyuan New Material Co., Ltd. was established in 2002, mainly committed to the development, production and sales of sound-cancelling, heat insulation and high performance heat resistant fiber products.

The main products: Fiberglass sound insulation cotton, Fiberglass pipe (Glass Fiber Tube), fiber Glass molded parts, basalt fiber sound insulation cotton, Fiberglass Needle Mat, basalt fiber Needle Mat, Fiberglass Heat Shield mat, basalt fiber Heat Shield mat, basalt fiber tube, basalt fiber strip, muffler Heat Shield, exhaust Heat Shield, Turbocharger Parts Heat Shield, purifier Heat Shield, Battery insulation cover, Generator Heat Shield, Engine sound insulation cotton, wiring harness Heat Shield, oil tube Heat Shield, fuel tank Heat Shield, Generator unit Heat Shield ETC.

FAQ

Q: What does fiberglass dust look like?

Q: What is fiberglass used in?

Q: Is fiberglass a good material?

Q: What is glass fiber made of?

Q: Can your lungs get rid of fiberglass?

Q: How can you tell if a bed is fiberglass?

Q: Is fiberglass used anymore?

Q: Does vinegar dissolve fiberglass?

Q: Do all mattresses contain fiberglass?

Q: How long does fiberglass stay in your lungs?

Q: What does fiberglass do to your skin?

Q: Why is fiberglass so good?

Q: Is all pink insulation fiberglass?

Q: What would happen if you ate fiberglass?

Q: Why is fiberglass in mattresses?

Q: Do all mattresses contain fiberglass?

Q: Why aren t cars fiberglass?

Q: Why aren't cars made out of fiberglass?

Q: What weakens fiberglass?

If you don't use enough resin, the fiberglass may not stick to the surface properly. It can also lead to fiberglass fibers fraying and your final product could be brittle and weak. Make sure to prep your surface by doing a coat or two of resin on the substrate first.

Q: Does fiberglass come off in shower?

Hot Tags: glass fiber needled felt, China glass fiber needled felt manufacturers, suppliers, factory, Basalt Fiber Silencer Cotton, High Temperature Insulation Fiberglass Needle Felt, Exhaust Manifold Heat Shield, Basalt Fiber Needled Felt, Fiberglass Insulation Cotton, Basalt Fiber Silencing and Heat Insulation Cotton